WHITE ABL

WHITE ABL tube – resource conservation par excellence

| Basics |

| ||||||||

| “Made by EGYTUBE” – our advantages at a glance |

| ||||||||

WHITE ABL 250/12 and 350/15 µm – a unique combination of resource conservation and complete emptying

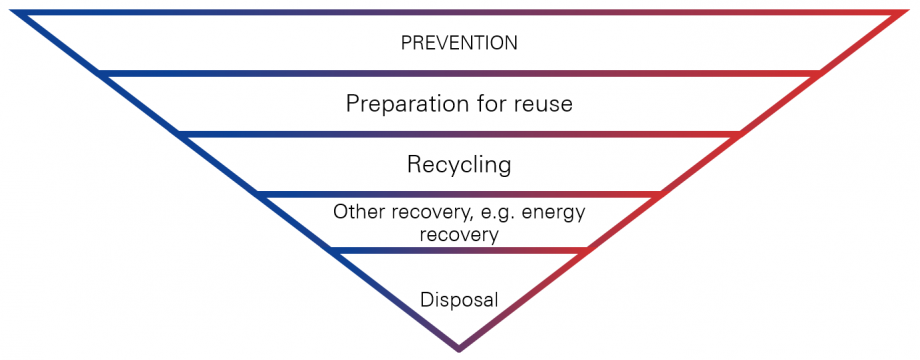

Did you know that the packaging law considers the avoidance of packaging materials top priority? We are pursuing exactly this approach with WHITE ABL tube by reducing the use of petroleum-based plastics in the body of the tube by half while simultaneously decreasing the wall thickness.

Compared to conventional laminate tubes, the use of petroleum-based plastics is reduced by over 50 percent by weight, substituted by natural calcium carbonate. This enables us to significantly reduce the CO2 footprint of the tube body.

In addition, the innovative material structure with a paper-like soft-touch feel helps avoid product waste by enabling more complete emptying compared to conventional tubes.

| Layer | Material |

|---|---|

| Inner layer (comes in contact with contents) | Polyethylene – calcium carbonate compound |

| Barrier layer | None |

| Outer layer |

Polyethylene – calcium carbonate compound |

Any questions about our tubes? Our packaging experts will be glad to advise you!

AREAS OF APPLICATION

IMAGES